Your cart is currently empty!

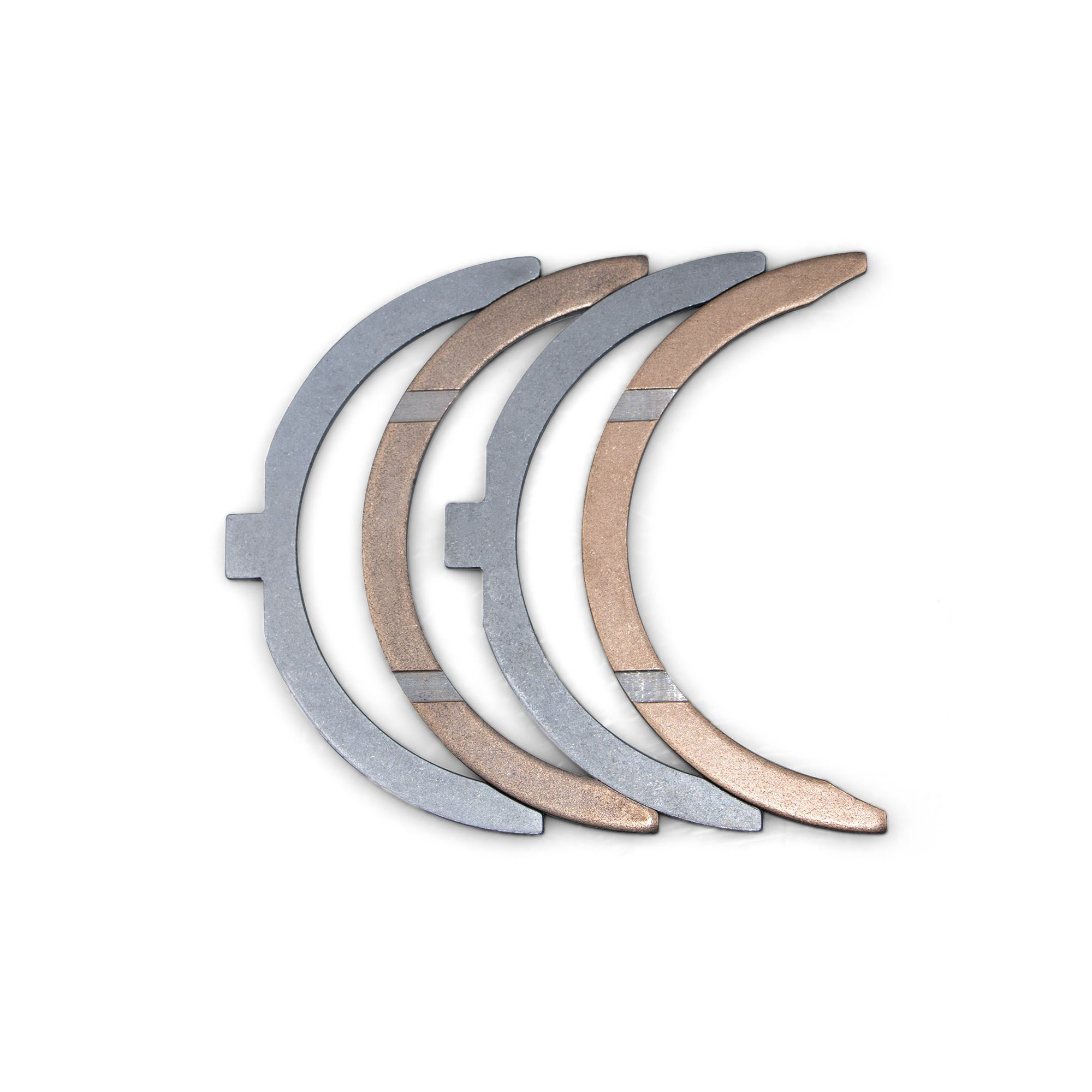

Thrust Washers

Thrust washers for the crankshaft are an essential component of the sliding bearings that provide axial fixation of the crankshaft in the engine block. Their primary function is to prevent the crankshaft from shifting forward or backward during clutch engagement or disengagement. Additionally, thrust washers ensure proper oil flow to the crankshaft’s thrust flanges, which is necessary to create a protective oil film. This film reduces wear and friction between moving parts.

Depending on the specific engine design, there may be two or four thrust washers. The thrust washer is shaped like a narrow segment resembling a crescent, made of a steel strip coated with a thin layer of anti-friction material, such as bronze or aluminum. These coatings reduce friction and extend the service life of the components. Thrust washers are replaceable engine parts, available either as sets for the entire engine or individually. Most washers include the following features:

- Grooves or channels for oil delivery to the working surfaces;

- Rectangular tabs or slots for proper installation in the engine block.

Typically, upper and lower thrust washers are not interchangeable.

As the crankshaft flanges and the washers themselves wear down, the clearance between the washers and the crankshaft flanges inevitably increases, leading to unusual noises or knocks, especially noticeable when engaging or disengaging the clutch. This is a crucial sign that the washers need to be replaced, and the crankshaft should be inspected.