Your cart is currently empty!

Valve Guides

Valve guides are an essential component of any automotive engine. They ensure the reliable movement of the valves during engine operation.

Technical Features of Valve Guides

Due to the high thermal and mechanical loads on these guides, component manufacturers are constantly improving their manufacturing technologies. Cast iron, which was previously used, is increasingly being replaced by modern powder materials. However, pearlitic cast iron is still in use.

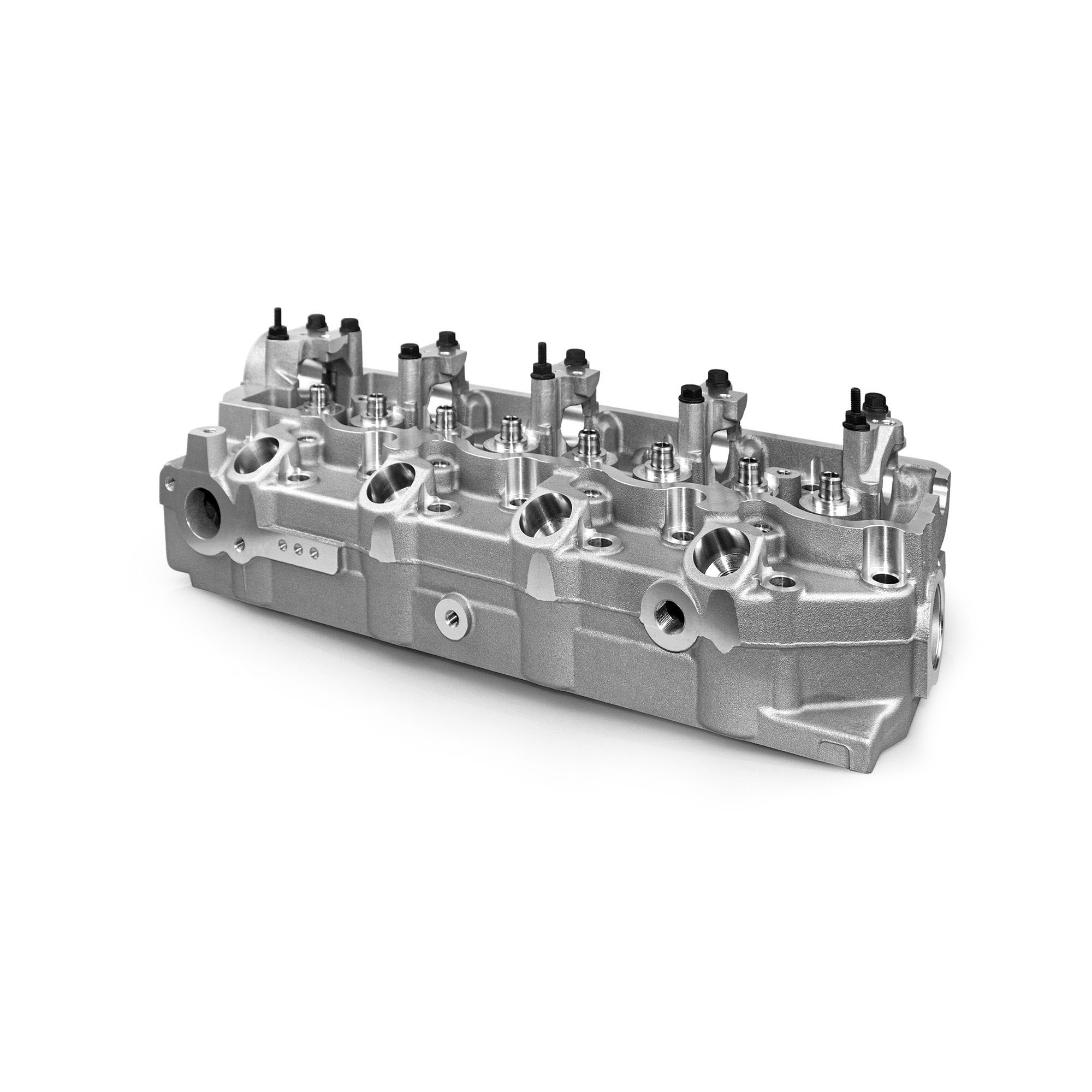

For nearly all engines, valve guides are separate components that need to be pressed into the cylinder head. It is very important for the surface of the guides to be precisely machined and free from defects.

Typically, the guides for intake valves are made shorter to protrude less into the intake channel, reducing the resistance to the flow of the air-fuel mixture. In contrast, the guides for exhaust valves are longer to better protect the stem of the exhaust valve from high temperatures.

Repair and Replacement of Valve Guides

Over time, the internal surface of valve guides wears out.

The selection of valve guides for engine repairs should be carried out by specialists. Guides are manufactured with high precision to ensure that the axes of the valve seat and the valve itself align correctly. An incorrectly selected guide can lead to excessive oil consumption, valve burning, and costly repairs. When replacing guides, it is crucial to adhere to precise dimensions to achieve the correct clearance between the valve stem and the guide hole.