Your cart is currently empty!

Pistons

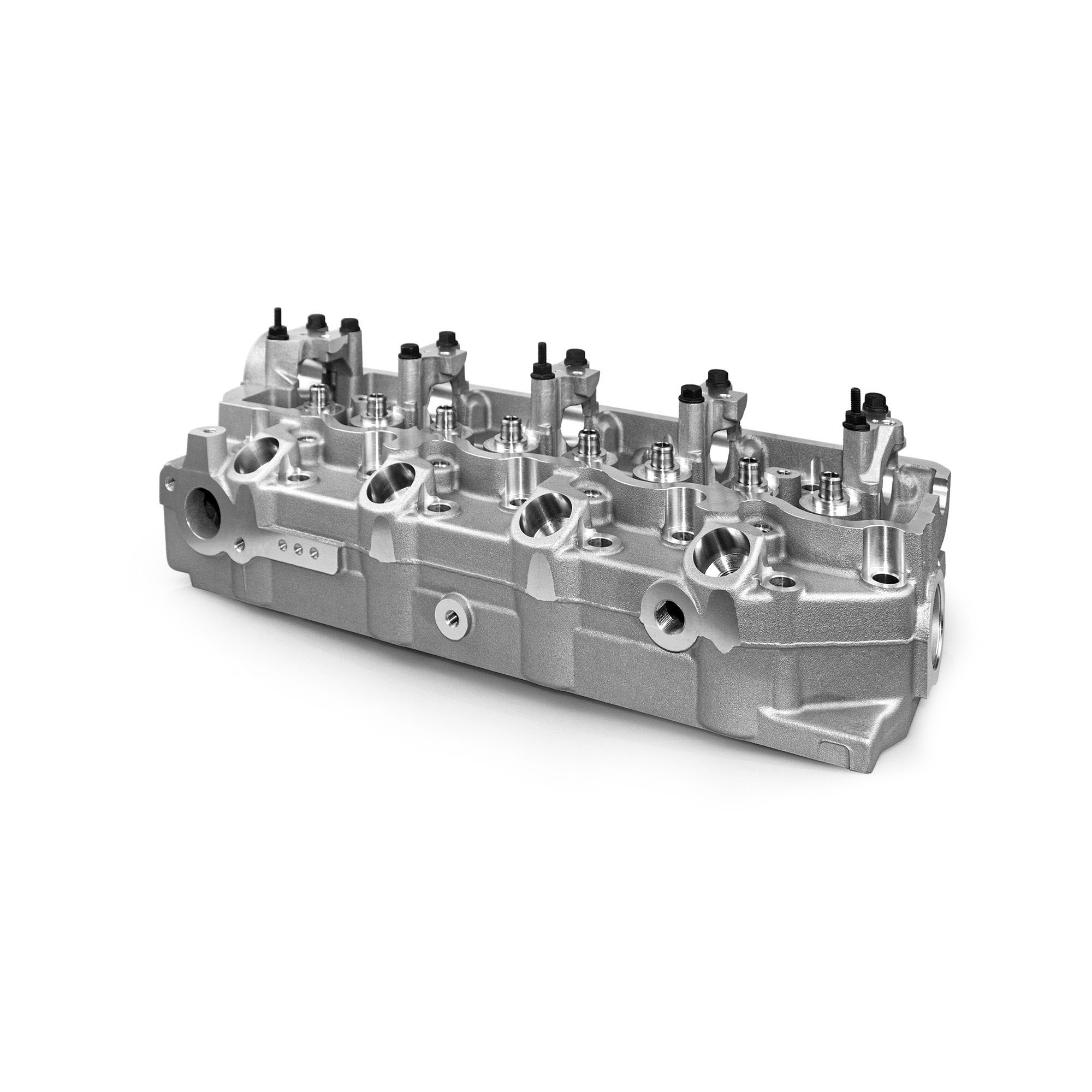

Valves

In a four-stroke internal combustion engine, valves play a crucial role—they control gas exchange and ensure the combustion chamber remains sealed during compression and the power stroke. There are two types of valves: intake valves, which regulate the flow of air or the air-fuel mixture into the cylinder, and exhaust valves, through which the exhaust gases exit the cylinder.

Modern automotive four-stroke engines use poppet valves, which consist of a stem and a head. The seating face of the valve head is ground at a specific angle to match the corresponding angle on the valve seat, ensuring proper sealing when the valve is seated. At the end of the valve stem, grooves are typically cut for valve collets, which secure the valve spring retainer.

Maintaining the combustion chamber’s seal is crucial for achieving high pressure during the combustion of the air-fuel mixture, which directly impacts the engine’s efficiency and power output.

Materials and Manufacturing

Valves are made from heat-resistant and corrosion-resistant steels due to the high temperatures encountered during engine operation, especially by the exhaust valve head:

- For gasoline engines – 900-1000°C;

- For diesel engines – 700-900°C.